-

Welcome to plumtriA platform for Research & Innovation

Welcome to plumtriA platform for Research & Innovation -

Looking for Funding?Check out the current open calls

Looking for Funding?Check out the current open calls -

Register today to start receiving our monthly newsletter

Register today to start receiving our monthly newsletter -

Looking to partner up?Search our list of registered profiles

Looking to partner up?Search our list of registered profiles -

You have questions on a particular funding programme?

You have questions on a particular funding programme?

Project GLAM - Metal 3D Printing - Building the Future Piece by Piece

Image

Imagine the ability to produce a critical spare part—such as a precision bracket used to securely mount components—within hours rather than weeks. This is the transformative potential of metal additive manufacturing, commonly known as metal 3D printing. This innovative technology is currently being researched at the University of Malta.

While metal 3D printing offers incredible rapid production turnaround and design flexibility, one key limitation persists: surface quality. Parts produced by powder bed fusion and other AM techniques typically exhibit high roughness due to incomplete powder melting and due to the so-called staircase effect, which results from the inherit layered nature of the process. These surface defects can compromise the mechanical and tribological performance of fabricated parts when compared to their conventionally manufactured counterparts. To address this challenge, the Green Laser Post-Processing in Additive Manufacturing (GLAM) project has been focusing on improving the surface finish through a combination of process optimisation and post-processing techniques.

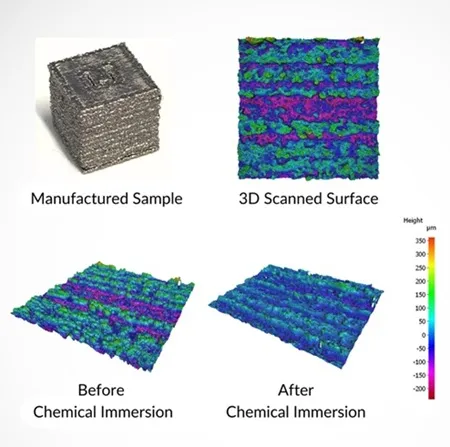

One of the principal focus areas of this project is to understand how surface roughness correlates with part performance. To investigate this, first an optical non-contact profilometer was used to assess the difference in surface roughness on a series of test samples. These include both as-built samples and samples subjected to a chemical post-processing technique involving immersion in a dilute acid solution composed of hydrofluoric acid (HF) and nitric acid (HNO₃). The figure below illustrates the change in topography between the before and after acid treatment. Preliminary results demonstrate that immersion in acid mixture leads to a measurable reduction in surface roughness; investigations are now underway to observe the subsequent effect of this topographical improvement towards wear resistance on components in contact under relative motion.

In parallel, the research team is also examining the ability of inherent surface irregularities - before and after post-processing - to act as controlled micro-reservoirs, reducing friction under lubricant-starved operating conditions.

The outcomes of the GLAM project have wide-ranging applications across sectors such aerospace, automotive, and biomedical engineering where components with complex geometries, extended fatigue life, and excellent tribological performance are essential. On a national level, this work has the potential to reduce reliance on imported components, lower production costs, and promote more agile and sustainable locally customised manufacturing.

This article explores the research being carried out by Mr Kris Bajada, Dr. Andre Giordimaina, Prof. Arif Rochman, and project lead Prof. Inġ. Glenn Cassar from the University of Malta, together with Dr. Inġ. Bonnie Attard from The Malta College of Arts, Science & Technology. The GLAM (SINO-MALTA-2022-13) project was financed by XJENZA Malta and the Ministry for Science and Technology of the People’s Republic of China (MOST), through the SINO-MALTA Fund 2022 (Science and Technology Cooperation).

Information and image source:

Attachments: External Link

plumtri is a platform that facilitates networking and knowledge sharing amongst stakeholders in the Mediterranean, involved in the spheres of research and innovation and serves as a 'one-stop-shop' for information on relevant funding opportunities and events.

Contact Us

Address:

Xjenza Malta

Villa Bighi,

Dawret Fra Giovanni Bichi,

Kalkara KKR 1320,

Malta.

(+356) 2360 2161