-

Welcome to plumtriA platform for Research & Innovation

Welcome to plumtriA platform for Research & Innovation -

Looking for Funding?Check out the current open calls

Looking for Funding?Check out the current open calls -

Register today to start receiving our monthly newsletter

Register today to start receiving our monthly newsletter -

Looking to partner up?Search our list of registered profiles

Looking to partner up?Search our list of registered profiles -

You have questions on a particular funding programme?

You have questions on a particular funding programme?

Project GLAM: Making Metal 3D Printing Shine

Image

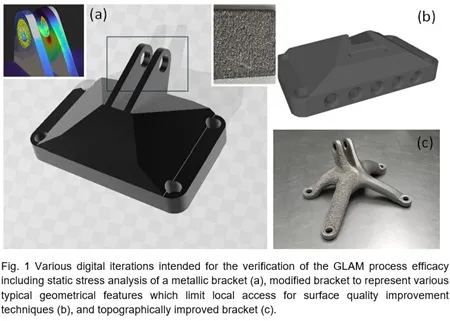

Metal 3D printing, or additive manufacturing (AM), has revolutionized industries by enabling the creation of complex components with unparalleled design freedom. However, a persistent challenge has been achieving smooth surface finishes, particularly in techniques like Electron Beam Powder Bed Fusion (EB-PBF). Enter the GLAM project, a collaborative endeavour between the University of Malta and the University of Shandong (China), addresses this challenge. GLAM, short for Green Laser Post-Processing in Additive Manufacturing, aimed to refine the surfaces of EB-PBF printed parts, ultimately enhancing their performance and broadening their applications.

EB-PBF, while offering advantages in material efficiency and design complexity, tends to produce rough surfaces due to the high temperatures involved. This roughness can negatively impact crucial properties like fatigue life and wear resistance. These factors are especially important in sectors like aerospace, where the high strength-to-weight ratio of materials like Ti-6Al-4V (a commonly used titanium alloy) is critical.

The GLAM project approached this problem on multiple fronts, combining optimized manufacturing parameters with innovative post-processing techniques. Researchers explored two key post-processing strategies: chemical immersion and laser surface engineering. The University of Malta focused on chemical immersion, employing controlled etching processes to remove surface imperfections, while the University of Shandong handled laser surface engineering, using focused laser beams to smooth and refine the outer layer of the printed parts. The impact of these methods was tested and characterized using characterisation techniques like microscopy and mechanical testing to assess their surface roughness, tensile strength, axial-fatigue resistance, and even tribological (wear) behaviour. Results indicated that improving surface condition (upwards of 30% reduction in Ra roughness) enhanced mechanical response under load. While dry sliding friction showed limited impact, wear tests under lubricant-starvation conditions revealed significant reductions in wear rate after both acid and laser treatments. These results suggest that the removal of loose, semi-sintered powder and brittle metal protrusions from the as-produced surface creates lubrication reservoirs, lowering friction over extended periods. Digital simulation was also adopted to couple topological optimization with surface condition, overall aiming at the design of lightweight yet strong components.

Beyond the technical advancements, GLAM fostered valuable international collaboration and skills development. The project strengthened research ties between Malta and China, facilitating knowledge exchange and paving the way for future joint projects. Crucially, the expertise gained in AM techniques, software, and characterization methods has been embedded within the University of Malta, ensuring a lasting impact on its research capabilities. The enhanced printing strategies and parameter knowledge are directly transferable to other metal AM printers and AM technology, such as wire additive techniques, positioning the university at the forefront of AM research.

The project's findings have been disseminated through various channels, including publications in local media and presentations at international conferences, reaching both specialized and general audiences. The GLAM project demonstrates how focused research and international collaboration can overcome challenges in additive manufacturing, paving the way for higher-performance and more reliable 3D-printed metal components across diverse industries.

The GLAM project brought together expertise from the University of Malta, including Prof. Inġ. Glenn Cassar who led the project, Prof. Arif Rochman, Prof. Inġ. Ann Zammit, Dr Andre Giordimaina, Mr Kris Bajada, Mr Danjel Grima and Dr Inġ. Bonnie Attard from the Malta College of Arts, Science and Technology. The Maltese team partnered with fellow academics from Shandong University, China, including Prof. Guoxin Lu and Dr Qiag Wang from the AEEC Institute of Aeronautical Materials. The work described in this article was carried out as part of the GLAM (SINO-MALTA-2022-13) project which was financed by XJENZA Malta and the Ministry for Science and Technology of the People’s Republic of China (MOST), through the SINO-MALTA Fund 2022 (Science and Technology Cooperation).

Information and image source:

Attachments: External Link

plumtri is a platform that facilitates networking and knowledge sharing amongst stakeholders in the Mediterranean, involved in the spheres of research and innovation and serves as a ‘one-stop-shop’ for information on relevant funding opportunities and events.

Contact Us

Address:

Xjenza Malta

Villa Bighi,

Dawret Fra Giovanni Bichi,

Kalkara KKR 1320,

Malta.